It has been nearly two years since the 737 MAX was grounded in the aftermath of several crashes. After the redesign of a flight control system, the aircraft has been re-certified by the US FAA and EU EASA and is returning to the skies. Several US and international airlines have already returned their MAX aircraft to scheduled service with others to quickly follow.

One of the requirements for the return to service of this aircraft is that pilots undergo a training session in a simulator. The purpose of the sim ride is to familiarize pilots with the behavior and possible failure modes of various flight control and indication systems. The ride included demonstrations of the normal function of the speed trim system (STS) and Maneuvering Characteristics Augmentation System (MCAS) during a stall and failure scenarios of angle of attack (AOA) and airspeed indicators. Runaway stabilizer trim malfunctions and flight with manual trim were also included. Failures of the MCAS subsystem, which is unique to the MAX, were implicated as contributing causes in two crashes prior to the aircraft being grounded.

Preparation for the ride included an extensive computer based refresher course on MAX systems and procedures and a detailed pre-brief on the planned simulator training events. Flight in high fidelity flight simulators is considered equivalent to flight in an actual aircraft, but superior as a training device as many maneuvers and failure scenarios can not be safely accomplished in an aircraft. That said, the devices cost tens of millions of dollars and training time is scarce and valuable. My airline has procured nine MAX simulators for the purpose of re-qualifying all their pilots in as short a time as possible.

Stabilizer Trim: What Is It?

The events surrounding the grounding of the MAX center on the stabilizer trim system. I am going to attempt to keep my explanations in reach of a general audience with some basic understanding of the dynamics of flight. There are many online resources available for those who wish for a more in depth explanation of aerodynamics.

The horizontal wing on the tail of a conventional aircraft is known as the horizontal stabilizer (stab). The elevator is attached to the back of the horizontal stabilizer and is a primary flight control. It moves to change the pitch of the aircraft. The horizontal stabilizer itself also moves a bit to “trim” the aircraft for a particular airspeed. Change the speed of the aircraft, and the trim will need to be changed to prevent the pilot (or autopilot) from having to hold constant force on the controls. A pilot can release the controls of a well-trimmed aircraft without it wanting to climb or descend. This condition is also the most aerodynamically efficient configuration resulting in a smaller fuel burn.

On the 737, stab trim is normally controlled electrically by switches on the control column which are activated with the thumb. The switches (two for redundancy) control an electric motor which spins a large wheel next to the pilot’s knee on the center stand. This wheel is mechanically connected to a jack screw which physically moves the stab. The motor has two speeds determined by flap position. The slow speed is used for flaps up and the fast speed activates when the flaps are extended. This wheel also serves as a manual crank to be used if the electric motor fails. Accidentally leaving the crank handle extended is a self-critiquing error as the handle hurts like heck when it hits your knee (so I’ve been told).

It is impossible to miss this wheel turning as it has stripes painted on it. While flying manually (without the autopilot), the pilot will use the thumb switches to activate the electric trim, but when the autopilot is engaged, the autopilot keeps the aircraft in trim using the same system. Therefore, the trim wheel will be seen moving on occasion in automatic flight as the autopilot adjusts the trim.

Starting in the 80s on the “Classic” version of the 737 (models 300 through 500), Boeing introduced a trim subsystem known as “speed trim”. Speed trim would operate in manual flight under certain conditions should the aircraft deviate from the trimmed airspeed. As mentioned above, trim correlates to airspeed. This system would make trim inputs in opposition to any speed deviation to encourage a return to the originally trimmed airspeed. The important thing to note here is that the trim wheel might now be seen moving in manual flight un-commanded by the pilot.

MCAS: What Is It?

MCAS or Maneuvering Characteristics Augmentation System, is another trim subsystem which was introduced on the MAX aircraft. It was found during certification of the MAX that the aircraft had some unwanted handling characteristics when approaching a stall. Specifically, just before stall entry, and well below any normally encountered airspeed, control column pitch forces became lighter when they are required by certification rules to become heavier. MCAS was designed to run the trim forward under these specific conditions to counter this tendency. It uses the high speed rate of the trim motor regardless of flap position.

Why did the MAX handle differently than its predecessors? The aerodynamics is complex, but the larger engines on the MAX had to be placed further forward on the wing to ensure ground clearance. This and other design factors likely caused the handling differences. This is the source of some controversy about whether the MAX should have been given a separate type certificate, but reviewing that subject is not the purpose of this report.

One point I’d like to make about flight control augmentation systems in general is that they are ubiquitous and date back to the 1950s. The existence of an augmentation system does not ipso facto indict the underlying design, but rather is an engineering solution that enhances the flight characteristics of nearly all modern high performance aircraft. I have experience flying aircraft which were virtually un-flyable without augmentation. Even fly-by-wire aircraft flight control systems, which are common today, can be thought of as augmentation systems with 100% control authority.

Lastly, the most important part of the entire electric stab trim system is that it can be deactivated at any time through the use of two stab trim cutout switches located on the center stand directly behind the throttles. These switches remove power from the electric trim system and all subsystems including speed trim, autopilot trim, and MCAS. Following deactivation, the aircraft can still be trimmed by manually cranking the trim wheel.

The MAX Return to Service (RTS) Simulator Ride

The simulator session was scheduled for a two hour training event preceded by a one hour pre-brief. The session was designed to cover both normal and non-normal flight profiles. The normal profile included a demonstration of the speed trim system on a routine departure and the expected annunciations and flight control behavior during an approach to stall.

The non-normal profiles demonstrated trim system failures and angle of attack (AOA) and airspeed indicator failures. The trim system failures included the use of the Runaway Stabilizer non-normal checklist and immediate action items, and subsequent flight using only manual trim. The AOA and airspeed failure profiles were designed to replicate the startle effect and confusion that can manifest from multiple annunciations and aural warnings during this type of malfunction. Subsequent use of the Airspeed Unreliable non-normal checklist and known pitch and power settings were required.

The simulator used was a CAE 7000XR series high fidelity simulator with full motion and daylight wrap-around visuals. All of the training events were flown from SeaTac airport in VFR conditions. The sim was initialized for takeoff on RWY 16L with all preflight items having been accomplished. I was paired with a line first officer for the training event.

Speed Trim Demonstration

A normal takeoff and RNAV departure to 10,000 ft were accomplished. During the climb in manual flight, deviations from trimmed flight were purposely introduced through the use of increased or decreased pitch inputs on the control column. The speed trim system was then observed to make trim inputs opposite of the speed deviations to encourage the aircraft to return to its originally trimmed airspeed. Once the originally trimmed airspeed was re-achieved, the speed trim inputs were automatically removed by the system.

The speed trim inputs were accomplished by the slow rate of the trim motor as the flaps were already up. The effect of these inputs was subtle and easily overridden if needed.

Approach to Stall/Stall Demonstration

After level off, we each were directed to pull the power to idle but to maintain altitude in manual flight through pitch control to observe the annunciations and flight control behavior during a stall. The approach to stall maneuver has been a staple of airline training for many years, but typically the maneuver would terminate with the activation of the stick shaker stall warning followed by a recovery. It was felt that exploring actual stall characteristics was unneeded and possibly negative training as this situation would never theoretically materialize in actual line operations. A recovery would always be made upon the activation of the stick shaker.

In the aftermath of the Colgan and some other crashes which served to highlight concern about deficiencies in manual flight skills, the FAA introduced extended envelope training (EET). This training went beyond traditional airline flight training to explore flight handling characteristics in areas of the flight envelope that would never be expected to be seen in line flying. The new thinking was that having some experience in these unusual situations might be of use in case one ever developed.

We were asked to make nose up trim inputs down to the lowest flaps up maneuver speed and afterward to continue to maintain altitude through control column pressure alone. A number of visual and aural alerts displayed and sounded as airspeed continued to decrease. The aural "Airspeed Low" alert sounded followed by the "Buffet Alert" FMC advisory message. The pitch limit indication appeared showing that we were within 5 degrees angle of attack to stick shaker activation. The stick shaker activated upon reaching the airspeed where natural stall warning buffet is computed to commence by the stall warning yaw damper (SWYD) computer.

During this demonstration, rearward control column forces continued to increase. As airspeed decreased below minimum maneuver speed, the speed trim High AOA mode activated thereby adding nose down trim at the slow rate of speed (because the flaps were retracted). This served to increase the necessary force to maintain altitude. Note that the high AOA speed trim feature is not unique to the MAX, but is included on older 737 models.

Eventually, the trim wheel made an abrupt twitch forward at the high rate, but only for a fraction of a turn. This, our instructor told us, was the MCAS system becoming active or "waking up". What was happening behind the scene was the MCAS logic took a "snapshot" of the existing trim position when its threshold AOA was reached. It then calculated a maximum amount of trim that could be added. Should the trim ever meet this computed limit, the speed trim and MCAS system becomes inhibited for the remainder of the flight. A short time later, MCAS activated adding additional nose down trim at the high rate of trim motor speed. The control forces were now heavier, but still manageable.

Finally, the Elevator Feel Shift (EFS) module increased the system 'A' hydraulic pressure to the elevator feel and centering unit as the AOA approached its stall value. The elevator feel and centering unit is how any elevator force is transmitted to the pilots through the control column. Changes in trim go through this unit before they are felt by the pilot. This hydraulic pressure increase dramatically increases forward pressure on the controls and felt like someone was trying to jerk the controls out of my hands. Again, it should be noted that the EFS module is not unique to the MAX but is also included on earlier 737 models.

At this point the aircraft was in a full stall with strong buffet being felt. The controls could still be held aft, but only with two hands on the yoke and significant effort. We were then instructed to release back pressure and to let the aircraft recover and accelerate. The aircraft recovered quickly. The inputs previously made by MCAS and speed trim were automatically removed as airspeed increased and AOA decreased.

This was the end of the demonstration. Both of us ran through this event several times so that we were familiar with the sequence of alerts and flight control inputs. 737 stall behavior is benign with no significant roll or wing drop being noted. Recovery was prompt with back pressure release and flying airspeed was quickly reestablished.

Runaway Trim Demonstration

All aircraft with a powered trim system are subject to a condition known as runaway trim. Recall that elevator trim repositions the horizontal stabilizer in order to "trim" the aircraft to a particular airspeed. When properly trimmed, elevator stick forces are minimized. "Trim to relieve stick pressure" was the mantra when I was in USAF pilot training in 1982. It is still true.

The converse that a badly untrimmed aircraft is difficult or impossible to fly is also true. An inoperative trim system is sub-optimal, but one that continues to trim after the trim switch is released, or trims on its own can quickly create a dangerous situation. Stick forces will quickly become so unmanageable that continued controlled flight is not possible. This may manifest as either nose down or nose up trim. Neither is good.

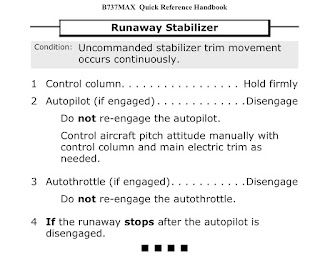

Fortunately, Boeing has always included a non-normal checklist (NNC) to address runaway trim. If correctly followed, this checklist will result in the runaway trim malfunction being corrected, or the electric trim system being deactivated. Recall that the electric system, including speed trim, autopilot trim, and MCAS, has always been able to be deactivated through the use of the stab trim cutout switches located on the center stand.

Our demonstration started with the instructor introducing a runaway nose down rapid rate trim malfunction. The most important step of any non-normal event in an aircraft is identifying the malfunction correctly and then applying the correct non-normal checklist. Many an accident has been the result of a wrong assessment of the problem or the application of the wrong checklist.

Recall that it is now normal for the trim wheel to spin un-commanded by the pilot in manual flight due to inputs by either the speed trim system or MCAS. Since the flaps were up and the aircraft was not in a stall situation, the fast rate trim activation immediately telegraphed a malfunction.This is how an MCAS malfunction might present along with some nuisance alerts. At this point, accomplishing the immediate action items (IAIs) of the Runaway Trim checklist on the Quick Reference Card (QRC) followed by the remaining steps listed in the Quick Reference Handbook (QRH) left us in a situation with the aircraft in manual flight with the electric trim disconnected by the stab trim cutout switches.

Immediate action items are steps on a non-normal checklist that must be performed from memory due to their urgent nature. The Runaway Trim checklist contains several of these steps which include disengaging the autopilot and autothrottles, controlling aircraft pitch and airspeed, and disconnecting the stab trim cutout switches if necessary. This checklist has remained largely unchanged over the many different models of the 737.

At this point, the aircraft had to be flown and trimmed manually using the trim wheel. There is a note in the checklist which emphasizes that reducing airspeed helps to relieve the air loads on the stabilizer which reduces the efforts needed to manually trim. Our malfunction was introduced at about 250 knots. Manual trim at this speed took some effort, but was easily achieved. Slowing to 210 kts allowed the flying pilot to easily fly and trim without assistance from the non-flying pilot.

Close crew coordination is of course required to split the duties of trimming and flying depending upon the situation. Flight in instrument conditions might require the flying pilot to direct the non-flying pilot to manipulate the trim. Instructive to me was the ease with which trim changes through the configuration process were able to be made. We were directed to go around on short final to see the trim changes needed for that maneuver. Using less than full power for the go-around made the maneuver very smooth and controllable.

Unreliable Airspeed Demonstration

One of the most disconcerting and dangerous malfunctions any pilot can face is the loss of reliable airspeed. Airspeed is the oxygen of controlled flight, and loss of reliable airspeed must be quickly recognized and corrected or ameliorated for a successful outcome. The importance of this instrument is why there is a lot of redundancy built in. The 737 has two primary and one auxiliary pitot probes used to measure dynamic air pressure which is then converted to airspeed measurement for the pilot's primary airspeed indicators along with an auxiliary airspeed indicator.

In addition to the direct measurement of airspeed, the 737 has displays of groundspeed derived from the air data inertial reference unit (ADIRU). While airspeed and groundspeed are not the same, at low altitudes, they are close enough to be useful.

Our demonstration simulated a bird strike or similar damage on takeoff which disabled the captain's alpha vane AOA transmitter though we were not informed of this beforehand. Immediately after rotation, a cacophony of alerts sounded accompanied by numerous messages on the displays. The indications included AOA Disagree, ALT Disagree, IAS Disagree, Speed Trim Fail, Feel Diff Press, along with erroneous airspeed, altitude, and flight director indications. The stick shaker sounded and did not cease for the entire demonstration.

As I mentioned above, the most important thing in any non-normal situation is to recognize what has failed and more importantly, what has not failed. A quick scan of the first officer's and auxiliary airspeed indicators told us that it was my instruments that had failed as the other two instruments were in agreement. I transferred control of the aircraft to the first officer who continued the climbout as I then referenced the Unreliable Airspeed checklist.

This checklist is fairly straightforward directing the autopilot and autothrottles to be disengaged if engaged. The flight directors are not to be used as they may also give erroneous information, and lastly for complete airspeed failure, some known pitch and power settings are given which are calculated to keep the aircraft from stalling or overspeeding.

We explored setting these values to see the performance of the aircraft with flaps both retracted and extended. The checklist values will keep the aircraft safe until a more detailed chart in the quick reference handbook, which uses aircraft weight, altitude, and phase of flight to set pitch and power, can be referenced.

Since our situation resulted in useable airspeed indications for the first officer, returning the aircraft to the airport was a matter of accounting for the nuisance stick shaker and other alerts, accomplishing the appropriate checklists and landing. We had been advised to bring ear protection for this segment, and it was worthwhile advice.

Changes Made to the MAX

The changes made to the MAX center around added redundancy to the Speed Trim System (including MCAS), and the Flight Control Computer. Input is now used from both AOA vanes and compared before being routed to the MCAS system. Previously, MCAS received input from only one AOA vane. A difference between input values from the two sensors will inhibit the system. New logic has been added which limits the amount of trim that the MCAS system can add. An exceedance of this limit also inhibits the system.

Additional safeguards, redundancies and self monitors have been added to the flight control computers themselves to prevent erroneous stabilizer trim commands. The odds of a runaway trim scenario are now effectively nil, but the runaway trim procedures and checklists will remain as immediate action items on the quick reference cards and handbooks.

Conclusion

I published my impressions of flying the MAX back in 2018 after I first flew the aircraft. I thought it was a great flying machine back then and I think it will be better than ever after its return. Was the aircraft as well designed as it could have been? Perhaps not, but then in no human endeavor is perfection ever achieved. I do not mean to denigrate the seriousness of the accidents that occurred nor the memory of those lost. Airline crashes are nightmares for all involved.

That said, underlying causes of any accident are complex and many differing narratives develop, some with agendas of their own. Causal chains behind any accident must be considered in total. A focus upon one aspect of an accident in isolation will inevitably lead to a missed or wrong conclusion.

Having now flown both the old and newer versions of the MAX, I am more convinced than ever that this aircraft is rock solid, whatever discrepancies there were have been corrected, and that it has a bright future as the preeminent narrow body airliner.

Captain Rob Graves is a veteran airline pilot and retired Air Force officer. He currently flies a Boeing 737 for a major American airline where he has over 30 years of experience. His Air Force career included instructing future USAF pilots in the T-37 primary jet trainer, aerial refueling in the KC-135 Stratotanker, and conducting worldwide logistics in the C-5 Galaxy cargo aircraft. He is the author of This is Your Captain Speaking, an aviation blog. It can be found at robertgraves.com.